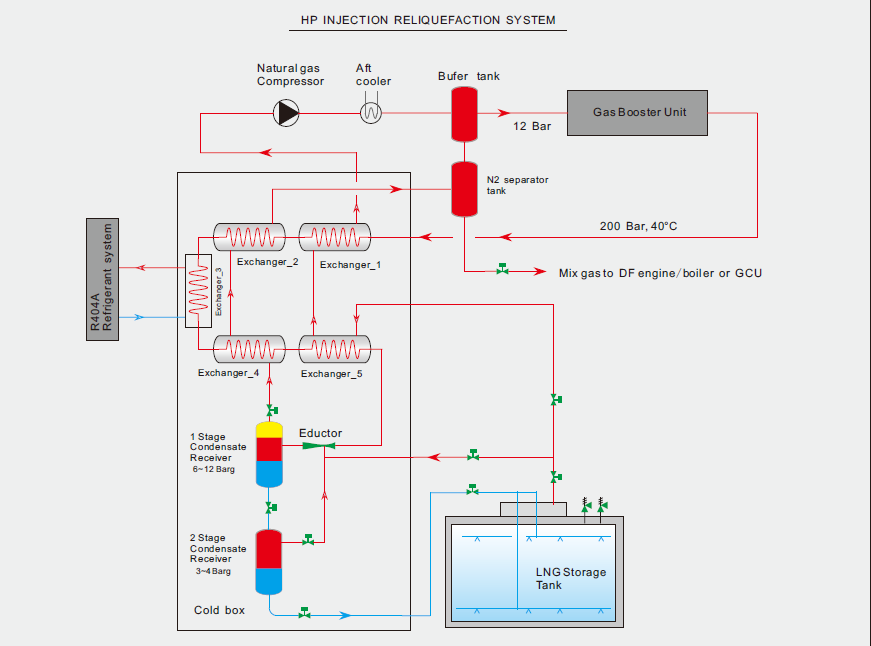

High-pressure jet reliquefaction system

The evaporation gas in the LNG storage tank is pressurized to more than 200 barG after multi-stage compression, thereafter the compressed high-pressure gas enters the cold box and is cooled by pre-cooling heat exchanger, refrigerant evaporator and heat exchanger in turn before gas enters the eductor for expansion. After the expansion the gas-liquid mixture formed after expansion enters the separator and the LNG liquid is separated into the LNG storage tank. The gas in the tank is sucked out by the eductor and BOG compressor for the next round of compression and refrigeration cycle.

System features

- The system process is simple, the main refrigeration component is the injector, its structure is simple, safe and reliable, no maintenance

- Modular design, save installation space

- The unit power consumption is about 0.55~0.65KWh/kg LNG

- It is suitable for the needs of small and medium-sized LNG carriers and LNG fuelled ships with large tanks where the boiloff gas development needs to be controlled

Download more information >